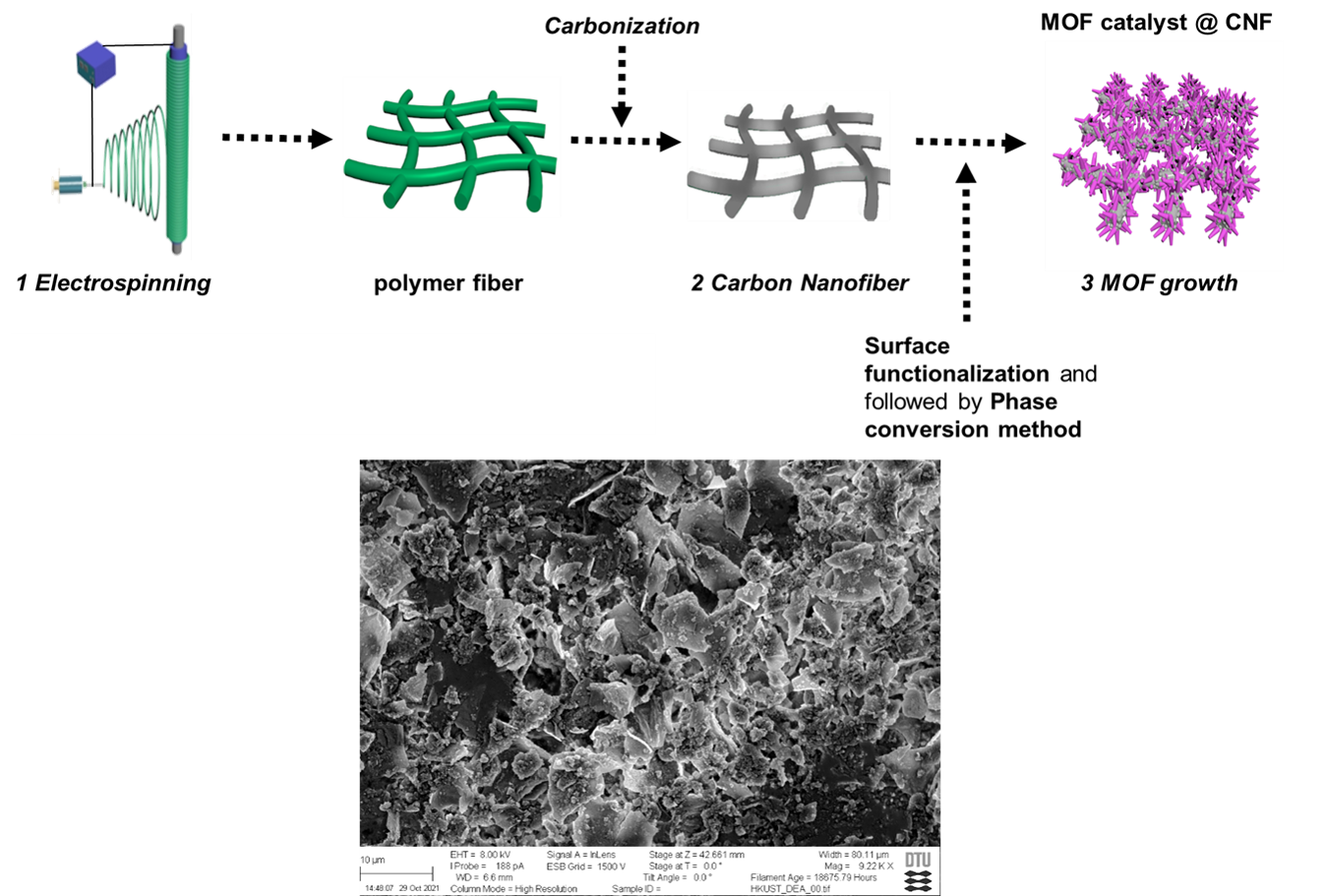

The main aim of this project is to develop and implement an electrochemical system having a highly selective and electronically conductive MOF catalyst with a robust gas diffusion electrode (GDE) designed for use in a CO2 electrolyzer setup. The developed electrolyzer setup with modified GDE is expected to be capable of producing a selective product with FE >70% and current densities over 200 mA.cm2 alongside long stable operation. Such GDE structures can be made by insitu grown MOF as a catalyst on carbon nanofiber matrix, a technique that has recently been developed at DTU Energy [16]. The underlying issues of low conversion efficiencies, selectivity towards specific targeted products, and a lack of stability under operation conditions will be addressed through the development of novel, stable MOF catalyst in unique GDE assembly approaches. Thus, our hypothesis is that the unique electrode architectures with MOF catalyst can improve the efficiency and selectivity of the ECR of CO2.

Planned research:

There is a necessity for synergetic or concurrent reactions to take place on the catalyst surface owing to the complexity of the CO2 reduction pathways; this can be easily realized by MOF structures where the metal center and organic linker each act as a functional element. Initially, in our project, certain MOF structures based on suitable metal centers with their improved catalytic and electronic properties will be chosen for our experiments based on related work reported in the literature [17],[18]. In further studies, new and more specific MOF structures with bimetallic or multimetal complexes will be developed explicitly to improve the selectivity of the CO2RR towards C2 compounds. Also, in this project, we propose the use of electrospinning method because it provides the possibility of fabricating the GDE in a quick and controlled fashion with small fiber diameters, high surface area, and a hierarchical pore structure. The insitu growth of MOF structures on carbon nanofibers using electrospinning will be evaluated as one option since it can be utilized to a) supply molecular dispersed electrocatalytic centers and to improve the selectivity by confining the pore space to reduce side reactions, b) increase the three-phase boundary (TPB) and to enhance mass transport, c) improve the mechanical stability of the GDE and d) to avoid leaching of the catalyst in harsh electrolyte environment. Furthermore, it is known that the flow cell electrolyzer does have huge ohmic losses due to the ionic conduction across the liquid electrolytes [20]. Thus, zerogap electrolyzer without any liquid electrolyte chamber would be designed and developed at the later stages of the project, and carbon balance issues would be addressed. Finally, In situ studies using chromatography and IR/Raman in monitoring of the products from the reduction reaction and evaluation of the real active sites in the catalyst respectively, would be devised to aid the research.

Project task to be carried out:

- Screening and development of new MOF structures with relevant metal atoms and analysing the same for fundamental catalytic activity, selectivity and stability.

- Improving the conductivity and hydrophobicity with the addition of certain nanofiller materials during MOF crystallization.

- Combined preparation of MOF structures with bimetallic or multimetal complex catalyst and carbon fibre felts using electrospinning process.

- Insitu IR/Raman characterization of the catalysts developed for understanding the interactions between the metal atom or cluster present in MOF structures and CO, which helps us in understanding and tuning the ECR.

- Modification of the GDE configuration in a way that improves the triple phase boundary between conductive substrate, electrolyte and CO2 and its evaluations through halfcell measurements.

- Including the study of the chosen electrolytes and its accelerated degradation due to its harsh conditions. Also attempt in solving the issues related to the CO2 crossover from cathode to anode while in operation.

- Setup and utilize a labscale electrolyzer cell/stack to test the MOF based GDE for CO2 reduction and understand the macromolecular structure-function relationship (eg. Assembly thickness, distribution of metal centers, porosity, wettability, etc.).